Finish off the first cassette unit.

It sounded so easy - we'd virtually finished at the previous meeting, but the final assembly just tightened everything up and although it did work, it was very tight. Furthermore, the sliding together became more and more granular - scratchy - each time.

We took it all apart and tried polishing everything, to no avail. We were reluctant to try greases or oils, because we might be relying on contact for electrical contact, but a squirt of contact cleaner made no difference. We also reduced the lengths of angles on one side, to the minimum - tidy, but not smooth. It was very frustrating.

After lunch, we took it all apart again and doubled/tripled the masking tape spacers we'd fitted between the pieces of angle - it was better - greater clearance was needed. Then, as a last resort, Geoff cut away the end 50mm of the MDF base underneath - it worked! We repeated it at the other end, screwed the loose running rail down, made up the angles for the other end, and fitted them. Bootiful!

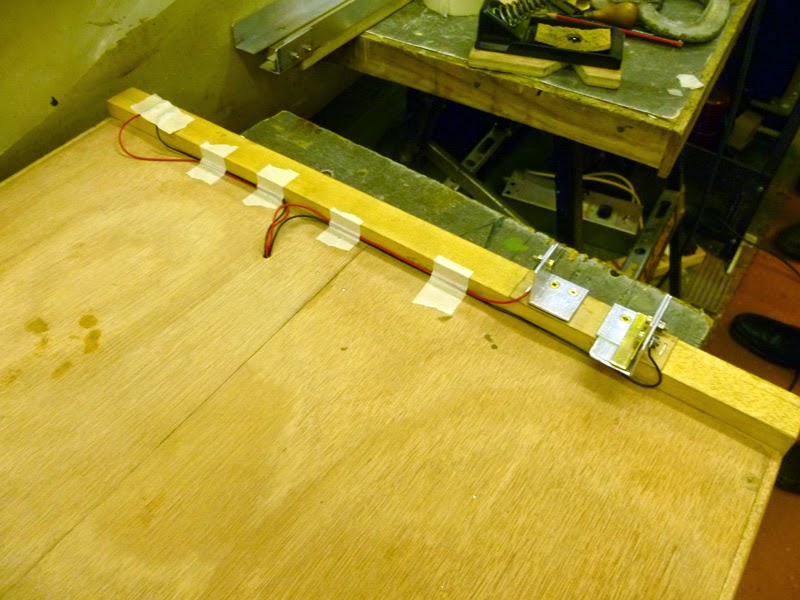

We had a working cassette, but now we needed power. The fiddleyard board is a redundant, hollow, ply faced door - light, but flat. We had fitted an 8-way plug into the loom, extending the last two sections on the main board (3 wires). A neat hole was cut in the underside of the door, and the socket fitted.

Wires were run through a small hole in the top face, to the fixed cassette units. The two on the left are for the line going to the mine. Yes, we've got to make a duplicate base for that line too.

Most engineering companies have a quality control department, and we had Laurence, to cast his eye over the assembly. A big thumbs up.

And also he'd brought a 'vericle' along as an extra test.