Wednesday 29th September 2021

Wednesday 22nd September 2021

Wednesday 8th September

Wednesday 1st September 2021

Worklist:

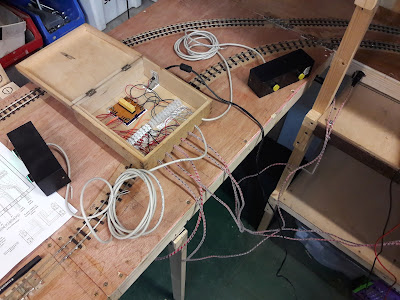

Connect the new loom wires to the control panel.

A simple description, but it took the whole session to complete. It started with a chart/table to correlate and record pin/wire numbers to track section and point switches. The engine shed board was fully documented and the loom wires soldered to the appropriate pins in the control panel. The 4-wires for the fiddle yard posed no problem. The mason's board followed, but the initial test showed two reversed wires, which were easily corrected. However, after completing the wiring of loom to panel, a whole block of track sections were not working. The problem was soon identified - the sections had all been connected 1 pin out (an easy mistake after a long day). A few minutes to resolve and all sections were working....... except for the fiddle yard. Try as we might, we couldn't find the breakdown. In a true lightbulb moment, Geoff remembered that the fiddleyard had its own bank of isolation switches which were off! We were appalled that we had forgotten this basic part of the layouts operation, but that's Covid for you. However, we had completed the wiring of loom to panel and it all worked.