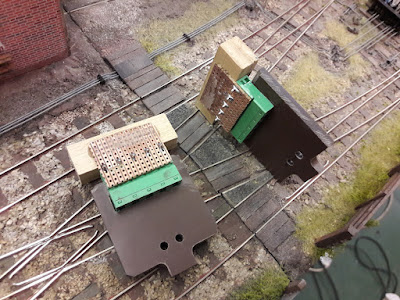

Lighting supports and holder

LED testing

Stock testing

Geoff had been busy and produced the four 15mm copper pipe posts for the lighting. These were shaped using a bending 'fixture' made for the purpose. He'd also made and fitted the socket-blocks to locate the ends of the pipes on the trestles. The height and forward 'throw' were guessed and adjustment is available, if required. The pipes will be prepared and painted in our standard dark grey, which hopefully, will make them less visible.

These were temporarily slung from the supports with wire loops, which we soon realised offered the option for the gutters to be rotated in the cradles (to shade the lights from the public side), which could be tested during experimentation. Stephen had also brought a selection of old LED strings - one was white and one was multi-coloured. Both were tried in the silvered gutter.

The coloured set (on the white setting) were considered not bright enough although the range of colours could be useful to add a touch of colour. The plain white string was better and so two further lengths (bright and warm white) will be purchased.

After lunch, the layout was hoovered and the track cleaned. 'Approved' stock was loaded into the cassettes and a running session took place.

As usual, the session raised a few issues both operationally and with stock. On their first run on the layout, the brake wagons at the ends of Geoff's tipper wagon train were lifted into the air when the iron dropper was strongly attracted by the uncoupling magnets. We also found yet again, that the station area was easily 'locked-up' with stray items of stock. These issues will have to be overcome in readiness for the shows. However, it was great to play trains again.

Stephen had brought the order of FR black fabric he'd received for the drapes, which looked superb when handheld in-place. The final dimensions and Velcro fixing points were agreed. His wife, Christine, has offered to make up the drapes.

All-in-all, a very satisfactory day.