Continue with wiring the Masons board uncoupling magnets.

Laurence preparing for a family wedding, so just two this session, which ended a bit early due to other commitments.

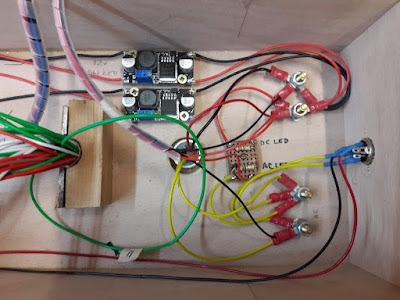

After a quick review of what wiring was outstanding, Stephen asked Geoff for a wiring layout diagram to clarify exactly what was needed. It was more difficult than anticipated, but served as a useful exercise for both. With the diagram totally absorbed, a missing pair of wires (servo 5v & ground) were added between the control panel and the engine shed board. On the Masons board (below) the connector block was repositioned to keep the servo wires short enough to obviate extensions. The servos were then wired into the block. It was then possible to plug the test unit into the Servo Control Board on the engine shed board and operate both servos for the uncouplers. Progress.

A few more wires were added to both boards to complete the system. Good progress!

The servo-powered units (points, uncouplers and any other accessories) require an on/off switch. Rotary switches are used for the points as these also indicate the route. For the magnets, Stephen had bought some miniature SPDT switches for the uncouplers and so a quick exercise was undertaken to confirm the position of the switches. These will throw up/down, but will require a master reversing switch to change between workshop and exhibitions where the control panel orientation is reversed! The additional 'accessory' is intended to be a door into the masons building/yard. There are 3 more channels available on the servo control board, but additional wires would need to be fitted into the loom to make use of them. They would have to be worth it!