Worklist:

Fit new rainwater pipe.

Complete foliage around pipework (track leading to the fiddleyard).

Fit magnets to engine shed.

Add foliage to the long fence.

Add weeds to base of all buildings.

Assess the pallets and crates printed to date.

The third downpipe needed a double swan-neck, which Stephen fabricated from 4mm plastic tube. It took a fair bit of trial and error to get the joints correct, then a lot of filing to achieve the final shape. This was spliced onto 3+ lengths of 3D printed downpipe, and suitably weathered.

|

| Main building cladding, windows and rainwater goods are all 3D printed. |

Geoff continued to build-up the foliage on the pipework frame looping over the track going into the fiddleyard.

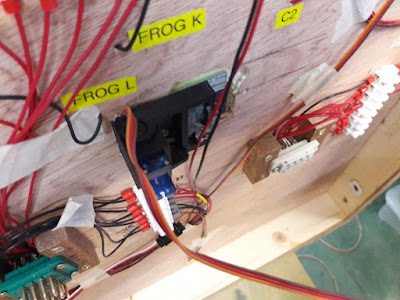

The engine shed is located over 4 vertical cocktail sticks, but is not fixed down, meaning it could fall off in transit. Rather than bolts, Stephen chose magnets - round magnets in a bucket (below) and rectangular magnets in a plasticard toolbox. Both were glued to the brick plinth with epoxy glue, 'diagonally opposed'. Countersunk holes were made in the plaster floor and 4mm screws inserted through to the plywood below. Both ends of the building were now perfectly held in place, but it can be removed for access to the lighting and the interior generally.

Geoff moved on to applying foliage to the long, bare Peco fence running up to the bridge. A variety of materials were used, starting with PVA, then a light spray of isopropyl alcohol diluted with water, which allowed to glue to spread more easily.

Both then moved on to applying small amounts of foliage along the bottom of the factory buildings and the cottages. Mostly subtle hints of weeds with occasional long grass clumps made from cut-down self-adhesive 'dots' of grass and a few electrostatic grass clumps.

Finally, an array of old 3D printed pallets was amassed, with many stacked and glued together to see how it might look. These were printed from drawings created 'in-house', but Geoff had also been experimenting with newly downloaded files, with varying success. Some of these included timbers which were far too thick to be used, often due to poor draughtsmanship. A selection of solid cases were also discovered which should make for an interesting yard. Geoff jokingly suggested that the front building could become a pallet/crate manufacturer. That's not a bad idea!

Stephen had made up one of the new flat wagons, but didn't have suitable wood for the decking and ends. Geoff had printed a few more wagons 'for homework' and supplied some of the basswood sheeting used on the prototype and the original stone wagons.

|

| That water tower still needs a feed pipe! |

|

The end of the layout

(so far....) |