Start developing the drop-down uncoupling magnet mechanism.

Geoff had been under-the-weather last week and this week, Laurence was sensibly avoiding the extreme heat of the last few days.

Geoff assembled a variety of mechanism elements that he had developed for his 00 layout. These comprise 2no. 3D printed units - one for fixing to the layout and another to house the moveable plate for the neodymium magnet. He had produced numerous variations to suit different situations on the layout. Interestingly, some designs housed the servos on the base, but also had a few on the moving plate. Components for a basic type were selected. The units are designed for a single magnet with steel rod sections atop the flat rectangular magnets, to extend the downward-pull field required for Sprat and Winkle couplings. Our requirement now was for sideways attraction of the Kadee drop-bar provided by two side-by-side magnets. Some experimentation was required.

A rig was assembled to assess the required proximity of the magnet to the track - i.e. how big would the hole in the baseboard need to be? This confirmed a standard hinge was suitable and indicated the sort of packing required. After more experimentation, it appeared that the fields of the current stock of magnets varied from the originals, and a central spacer was now required to obtain maximum sideways throw.

All components were glued onto a keeper plate and the assembly glued onto the hinge base plate.

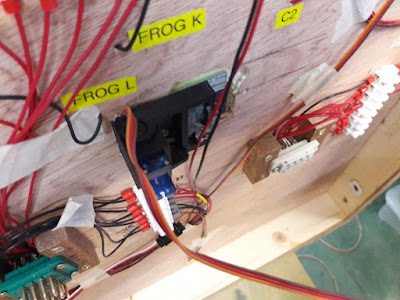

As no thought had been invested in allowing space to locate the magnet units (!), it was decided to fit the engine shed siding magnet first as it was the easiest to fit, requiring (almost) nothing to be moved. The position was marked underneath, a hole routed out (a dedicated ply spacer was made for the router) and the unit screwed in place. Lessons were learnt at every stage!

A plug-in servo tester/adjuster was used to test the installation, and proved it worked and was properly housed. A small square of foam was fixed on the baseboard to obviate 'slap' experienced on the 00 layout.

A bit of hand-shunting proved that we had a working uncoupling magnet. Finally, an assessment was made of the options and work required to move wires and connector strips for the other three units. One for next week.

Whilst dismantling the layout to fit the unit, the end of the 'Quarry tunnel' was visible. Apart from the vertical support on the corner, the tunnel is open at the back for access to track and stock.