Worklist:

Check over control box to remind ourselves what is in there, then....

Make sure we know what it all does.

Drill holes in new backscene for the control box fixing bolts.

Modify new bolts for leg fixings.

Paint some more of the back scenes.

It was interesting looking at and into the control box after such a long time. After a while, we'd worked out what most of it did. We then clamped the back scene in place, drilled the holes in it for the control box bolts and bolted the box in place. We were surprised how near the end of the layout the control box was. We then noticed that the control box prevented fixing a lighting pole to the end leg, which we couldn't accept. Another concern was that the position of the uncoupling magnet in Edwards' yard, in front of the loading dock, was completely obscured by the loading dock roof.

|

| Original location |

We cogitated for a while and then decided to move the control box to the left - towards the centre of the two boards. The loom was the restricting factor and there wasn't much room for manoeuvre - maybe 80mm - enough.

|

| New location |

New bolt holes were drilled, tee nuts fitted and the box mounted. The hand-held controller plugs into the left hand side so by shuffling along a bit, the uncoupling magnet area is visible.

We've always meant to colour-code the bolts on the layout. The M6 hex-socket furniture bolts were standard length, but the remaining M8 hex-head bolts vary in length. The control box and leg bolts were duly painted AND, labels were applied to the boards identifying what went where. (We later plugged the original box holes to save time hunting for the tee-nuts!).

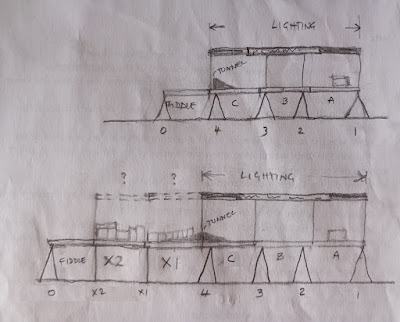

To test the panel and re-educate ourselves with the track sections, power was applied. The panel had been designed to operate in two modes. At an exhibition, and in the workshop. In the workshop, the new boards would run down a wall parallel to the main board via four additional boards, but in the opposite direction. The control panel was rotated 180 degrees, so the switch layout/notation had to work both ways up. The on/off, push-button section switches and point knobs were no problem, but the three rotary switches on the end determined which control panel (Main or Local) fed each of three zones on these two boards. However, we'd forgotten what the 3 zones were, so with the aid of a small track tester, we worked through all combinations and resolved the issue.

Two were obvious. One switch determined who controlled the 'mainline' along the front into the fiddleyard and one determined who controlled the rear hidden track to the quarry (fiddleyard). It transpired the third determined control of the engine shed area and didn't include Edwards' yard, which we had expected. However, as we don't ever envisage setting-up the reversed layout again, the rotary switches will be replaced with toggle switches, for simplicity. Luckily, we found our pack of coloured vinyl sheet to line-out the track diagram, and we'll try and come up with a way of defining the three zones on the control box.

The two leg bolts, initially secured with re-tapped imperial bolts, were replaced with long M8 bolts and colour-coded, to make Stephen happy!

The fun over, we got on with some serious painting, applying a coat of grey undercoat to the backs of the two back scenes.

We need to finish these and get on with 1 (or 2) lighting poles, a 'gutter' fascia and led lighting. There's trees to finish and plant, gutters and downpipes to fit on the factory buildings, wagon loads of stone to design and 3D print. Some people would be nice...

.jpg)