Geoff had met another modeller at the TDMRC open day, who described the excessive cost of van hire for the over 70's, so planning for three-car transport was top of the list. Two friends, both experienced exhibitors, would be approached in due course. Two new trestles would be required, plus extra lighting, extensions to the fascia, backdrop etc. Our existing trestles were very bulky, but a trial strip-down showed that they could take up less space. A third, decent sized car should suffice.

Worklist:

Discuss trestles (see above).

Print more windows.

Test the addition/fixing of glazing sheet.

Cut-out remaining openings.

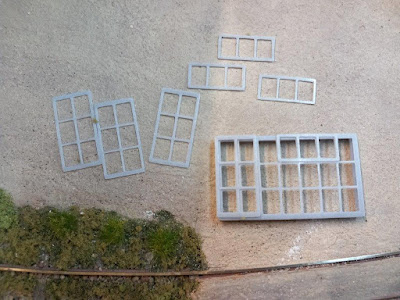

Firstly, the remaining windows for the separate building were printed and popped into place. We were very pleased with the effect. The glazing bars of the larger windows were found to be bowing outwards, which would not be acceptable when the glazing is applied.

Geoff moved on to drawing and printing the opening casements. Slightly wider horizontal and vertical frames will be laid flat or slightly ajar, with the underlying glazing bars removed, to create opening windows. They looked quite flimsy, but came off the 'build plate' easily.

As we have a large number of tests, failed and surplus window frames, the idea of making the separate building a sub-let unit a bespoke window frame maker could be a great choice!

Stephen had been working at home on the house & office buildings and brought them in for a 'fitting'.