Fully test the new section control arrangement.

Rectify intermittent point adjacent quarry signal.

Modify control panel sections to new configuration.

A few more weeds to the station area.

Bits and pieces of maintenance.

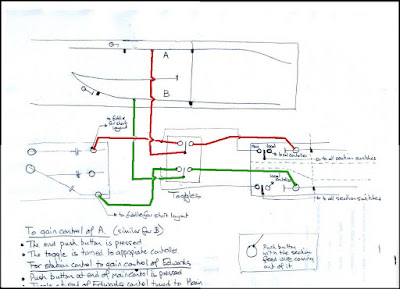

The full layout was set up and a loco run through all areas to test the new system. All switches and sections worked as required - a great relief. With so many section overlaps and switches, the ease of use was a key question, but again everything appeared to work quite rationally.

At the end of the last session, the point adjacent the quarry signal was playing-up. Instead of a lengthy investigation, a wire was loose on the point switch in the control panel - job done!

Geoff moved on the 'downgrade' the station area. He regularly says that it is far neater than preserved railways he's worked on, so out came the PVA, a suitable old brush and bags of scatter material.

The mainline track sections and switches (top) have been in existence for many years, but the wiring has been modified to make better use of them. Together with the new orange section, trains controlled from the mason yard can now pull right up to the signals.

Recap: When a train approaches a signals and stops, the operator selects Frame on the appropriate 'action' panel and the bell on the ground frame rings and the light flashes, alerting the station controller. Once the track is clear, the 'action' switch is turned to Sign, whereupon the light on the signal flashes to advise that the train can move into the station.